About the event

Aero-engines are astonishing engineering feats. They are tasked with the efficient delivery of thrust—some generating as much as 400 kN—whilst adhering to stringent emission and safety regulations. From the centrifugal force acting on each fan blade (equivalent to the weight of a double decker bus), to the high temperatures experienced in the turbine (well above the melting point of the blades themselves), there is no shortage of mystifying and intriguing facts about the engine. Following a brief overview of the aero-engine and its operation, I will talk about three research themes that lie at the intersection of turbomachinery aero-thermodynamics and data-centric engineering.

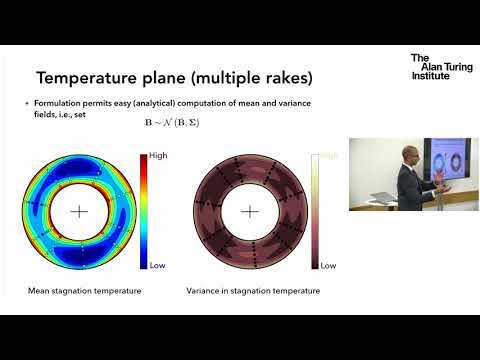

The first theme concerns the way one designs and manufactures blades. Here ideas from the field of subspace-based dimension reduction can play a powerful role in ensuring more efficient preliminary and detailed design workflows, while simultaneously cutting down the costs associated with manufacturing to certain tolerances. The second theme revolves around how one experimentally estimates uncertainty in engine sub-system- and system-level performance; an extremely important task as greater uncertainties warrant either more instrumentation, higher quality of instrumentation, or the launch of a research program. Given that performance is estimated from numerous temperature, pressure and bleed measurements—each with their own precision and range—aggregating them to compute efficiency (even for a single sub-system) is a challenging task. To this end, I will present some solutions using the Delta method from statistics. The third theme I will discuss is computational fluid dynamics—our workhorse for estimating aero-engine performance in computer simulations. More specifically, I will outline both the aleatory and epistemic uncertainties in Reynolds average Navier Stokes (RANS) computer models in turbomachinery and the numerous strategies tailored at their quantification. The former largely revolves around ideas within the remit of polynomial chaos while the latter is based on machine learning approaches. Broadly speaking, more accurate computer simulations can significantly reduce the costs associated with expensive rig and engine tests.

Speaker: Dr Pranay Seshadri (University of Cambridge, UK)

Pranay Seshadri is a postdoctoral fellow at the Department of Engineering, University of Cambridge. He is also a Group Leader within the Data-Centric Engineering Programme, largely focused on aerospace. He obtained his PhD in turbomachinery and computational engineering at the University of Cambridge.

Data-centric engineering in aero-engines: Pranay Seshadri, Cambridge

February 19, 2024

4 views

2 min read

You may also like

Deep Dive into AI, Thought Leaders

Professor Gareth Roberts: “New challenges in Computational Statistics”

9 views

2 min read

8 views

2 min read

Deep Dive into AI, Thought Leaders

Professor Stéphane Mallat: “High-Dimensional Learning and Deep Neural Networks”

15 views

2 min read

Categories

- About AI

- Adobe

- AI

- AI ADVANTAGE TUTORIALS

- AI Art

- AI conferences

- Ai Engineer

- AI Explained

- Ai for Beginners

- AI for Daily Life

- AI for Developers

- AI for For Startups

- Ai for Healthcare

- AI in Popular Culture

- AI in Real Life by the BBC

- AI News

- AI Podcasts

- AI Science

- AI Technology

- AI Tools

- AI Use Cases

- Anthropic

- AWS

- ChatGPT Prompting

- Cold Fusion on AI

- Consumer Product Goods (CPG

- Creativity Squared

- Deep Dive into AI

- Dmitry Shapiro

- Eye On AI

- Featured AI Videos

- Foundational Models

- History of AI

- Introduction to AI

- Lex Fridman Podcasts on AI

- Microsoft

- MIT

- Natural Language Processing (NLP

- OpenAI

- Philosophy of AI

- Python

- Responsible AI

- Sequoia Capital AI Ascent

- Skill leap AI

- TED Talks

- The Ai Conference

- Thought Leaders

- University AI

- World Science Festival on AI

All Topics

- About AI255

- Adobe17

- AI135

- AI ADVANTAGE TUTORIALS169

- AI Art45

- AI conferences465

- Ai Engineer38

- AI Explained73

- Ai for Beginners23

- AI For Business15

- AI for Daily Life95

- AI for Developers118

- Ai for Education122

- AI for Family40

- AI for Fintech151

- AI for For Startups38

- Ai for Good28

- Ai for Healthcare113

- Ai for Kids12

- AI for Marketing36

- Ai for Parents6

- Ai for Teens27

- AI Hardware569

- AI in Popular Culture374

- AI in Popular Culture356

- AI in Real Life by the BBC26

- AI Law18

- AI Law & Compliance9

- AI News35

- AI PLATFORMS19

- AI Platforms24

- AI Podcasts197

- AI Science172

- AI Series by Centre for Eye Research14

- AI Smart Automation Conference12

- AI Summit London 202341

- AI Technology20

- AI Tools4

- Aidan Gomez – Cohere28

- Alex Karp – Palantir48

- Alexandr Wang34

- AMD7

- Andrew Ng48

- Anthropic6

- Artificial Intelligence & Machine Learning in Finance36

- Athens Roundtable on AI62

- AWS7

- BERT9

- BrXnd Marketing x AI17

- CALTECH18

- Cerbral Conference26

- Cerebraus72

- ChatGPT for Work Training62

- ChatGPT Prompting14

- Chinese Room Argument – Searle9

- Cohere165

- Cold Fusion on AI1

- Computer Science 188 UC Berkley25

- Computer Vision9

- Consumer Product Goods (CPG72

- Content Summit 202313

- Creativity Squared94

- CS50 Introduction to AI with Python at Harvard8

- CustomGPT.ai57

- Data + AI Summit246

- Data Processing13

- Data Science with ChatGPT by D. Ebbelaar9

- Davos on AI 202417

- Deep Dive into AI424

- DeepMind183

- Demis Hassabis12

- Dmitry Shapiro11

- Dmitry Shapiro8

- Elon Musk28

- Energy61

- Eye On AI262

- Featured AI Videos145

- Generative AI Foundations by AWS7

- Geoffrey Hinton88

- Google386

- Government & Public Services37

- Greg Brockman – OpenAI25

- Hard Problems of Consciousness18

- Harvard University8

- Healthcare Tech by Todd DeAngelis10

- History of AI14

- Hospitality & Tourism6

- House Judiciary on Gen AI & Copywrite8

- Hugging Face87

- Ilya Sustever29

- Intel32

- Introduction to AI62

- Jensen Huang13

- Langchain111

- Learn AI Art38

- Learn AI with IBM18

- Legal Services97

- Lex Fridman Podcasts on AI36

- LlamaIndex52

- MACHINE LEARNING COURSE – MIT21

- Machine Learning Course with Andrew Ng41

- Machine Learning CS22918

- Manufacturing93

- Marc Andreessen17

- Media & Entertainment18

- Meta45

- Microsoft53

- MidJourney8

- Military Readiness in the Age of AI6

- MIT56

- MIT Introduction to Deep Learning | 6.S19163

- MosaicML4

- Natural Language Processing (NLP63

- Neural Network91

- Nodes 202316

- Northwest Medicine Healthcare AI Forum7

- NVIDIA436

- OpenAI9

- Overview of Artificial Intelligence CS221 Standford19

- Philosophy of AI42

- Pincecone69

- Python27

- Python for AI27

- Quantum Computing in AI14

- Real Estate16

- Reinforcement Learning15

- Reinforcement Learning CS23415

- Responsible AI51

- Retail86

- Rise of AI Con 202324

- Runway150

- Self-Supervised Learning47

- Sequoia Capital AI Ascent4

- Skill leap AI67

- Software Development104

- Stable Diffusion16

- Standford AIMI Symposium _ Center for AI & Imaging7

- Standford U212

- Standford University173

- Stanford CS224N: NLP with Deep Learning23

- Stanford XCS224U: NLU I Intro & Evolution of Natural Language Understanding49

- Support Vector Machines (SVM29

- TED Talks40

- Teens in AI Podcast27

- Telecommunications72

- The Ai Conference51

- The AI Hardware Show22

- The Edge Summit33

- The Future of Brands 202333

- The Turing Test20

- Thought Leaders577

- Transformer Architecture40

- Transportation & Logistics31

- University AI213

- University of California, Berkeley53

- University of Cambridge23

- What is it like to be a bat? – Thomas Nagel35

- World Science Festival on AI17

Add comment